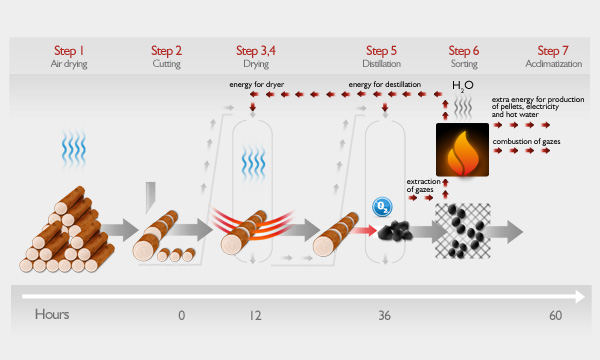

Charcoal

Production

Step 1 - Air drying: The wood is stored in outdoor warehouses in order to reduce moisture content. Depending on quality, season and temperature, it can be stored for up to 6 months.

Step 2 - Cutting: The wood is cut into regular pieces in order to create optimal granulation.

Step 3 and 4 - Drying: For a quick and even distillation, Gryfskand use the surplus of energy to pre-dry the wood before distillation.

Step 5 - Distillation: Distillation is the most important step in the production process. In this step, wood is carbonized and transformed into charcoal.

Step 6 - Sorting: After distillation, the charcoal is screened and controlled in order to fulfill our highly set standards. The undersized dust is used to produce briquettes and activated carbon.

Step 7 - Acclimatization: After sorting, the charcoal acclimatizes for several days, and the final product is stored in one of Gryfskand's warehouses across Europe.