Activated carbon filters

Production

Gryfskand's production of activated carbon is highly advanced and, from the beginning, it has improved the production process in order to meet high quality and environmental demands. Since Gryfskand also produces charcoal at the production site, which has an exothermic production creating excess energy, the need for fossil fuels in the production process is minimal. Like all Gryfskand plants, Hajnowka is independent of outside energy needs such as oil or gas.

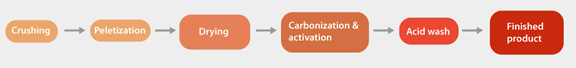

Below is a simplified production schedule:

- The raw material is crusshed into small pieces in a grinder.

- The small fractions of carbon is mixed with bindings and water and pressed into desired cylindrical shapes.

- The pelletizized pieces are dried in order to create a harder surface.

- The activation is the heart in the process of the production. The pieces are "activated" in big rotating kilns together with high heat and water steam. This process open up the internal pores in the carbon and creates a big internal surface with absorbation capacity.

- Acid wash is applied to some products in order to reduce the ash content.

- Depending on raw material and production process Gryfskand can produce a wide range of different products for various industrial needs.